It has been a long standing interest to learn to build stringed instruments. I worked for ten years as a woodworker/cabinet maker many years ago (70s -80s) and I acquired some tools and some skills to build furniture. As a totally self learned skill it was mostly a matter of reversed engineering with lots of lessons learned the hard way. We moved several years ago to a new home with a three car garage built with the understanding that 2 of the three stalls would be for shop space. My tools followed to the new location and got set down in the middle of and unfinished garage and I had to build the shop space around the disarray of tools and other items meant for garage storage. Our contractor at the time was a bit weak on planning and it turned out that several feet of my space was lost due to the need to build stairs and a landing to access the garage from the house. It has taken several years to finish the space and create a workspace conducive to building stringed instruments. Drywall, insulation, lighting, and heating had to be completed. Tools needed to be reset up and re tuned and tools acquired to be able to build instruments.

It is my goal to be ready to start production in the spring of 2008. additional tools need to be purchased such as a re saw bandsaw with a capability of at least 10 inches as my current saw only will re saw 6 inches. The larger re saw capability is needed to be able to slice billets into the thin lumber needed for instrument back and sides. Lumber can be purchased already dimensioned for instrument construction but at a premium price and I want to be as cost effective as possible in this endeavor. For the next several months I'll continue to build jigs designed to do the operations needed for accurate construction. I have three inital goals which include development of a short scale 000 body style guitar with the neck joined at the 12th fret---I find this to be the easiest to play guitar and most comfortable to hold. I want to develop an acoustic body upright bass with a small enough body to produce enough volume and tone for practice purpose but will rely on amplification for performance. And my last interest is in development of an electric bass with a chambered body. Visit this page from time to time to see how the project is developing. To start I figured I would post some pics of my shop as it is today.

Machine cluster in the center of the shop-6in. Rockwell jointer, 3/4-in. spindle shaper and Grizzly 15 in. planner

Charles Fox design side bender for shaping guitar sides

16 in. open end drum sander

Radial drill press

Horizontal boring machine (may sell to make room for more new machines)

Home built 3/4 in spindle shaper

Dust collection

Home built work bench

2nd. home built work bench

10 inch table saw

Compound miter saw

12 in band saw (to be replaced with a 14 saw with at least a 10 to 13 in resaw capacity "Grizzly or Rikon" however may keep this one for cutting curves so I will not have to be changing blades between operations)

corn stove ---- direct vent heater!!

Sharpening station

Duplicator

Band saw for resaw

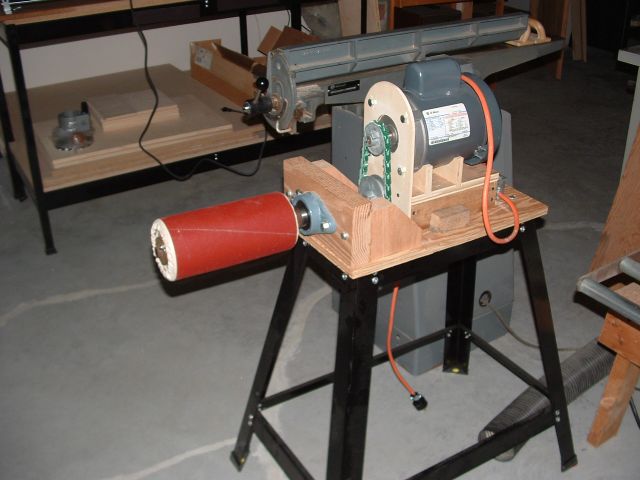

Pneumatic drum sander

Buffer machine